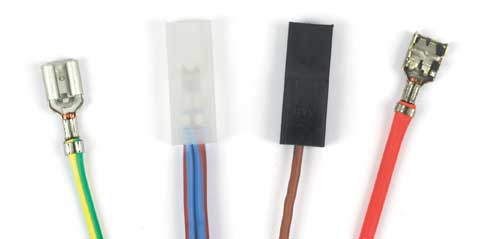

Traditional wiring

The Wiring for the production Department uses technologically advanced and up to date machines.

The processing involves cutting and stripping of wire, crimping of terminals and the insertion of capsules. Automated machines control crimping at 100%.

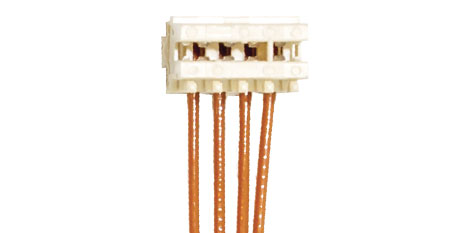

IDC wiring

There are a series of lines within the Gbm production dedicated exclusively to the manufacturing of IDC wiring insulation piercing connectors that are manufactured using special machines with presence and wire color sequence control.

Silicone glass cables with low insertion force straight terminals and 90° with insulating caps, male and cylindrical fastons

Silicone insulated cables and PVC 70 c° and 90° with electronic terminals, eyelets, female fastons 4.8 6.3 × 0.8 with safety caps

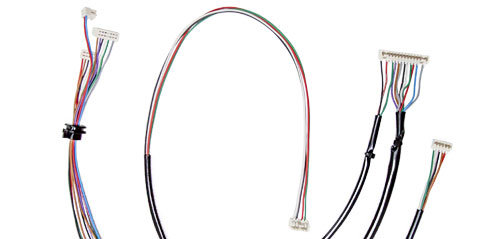

Special assemblies: Insert wires into terminal blocks, sheaths, crimps, TCO spies

Complex assemblies with insertion of sheaths, block fastons, colored and banding faston covers

Italiano

Italiano